Top throughput rates and high storage density in high bay and small-parts warehouses.

Pallet Materials HandlingSEMI SHUTTLE

Maximum flexibility for automated storage of various large and small load carriers in mixed operation

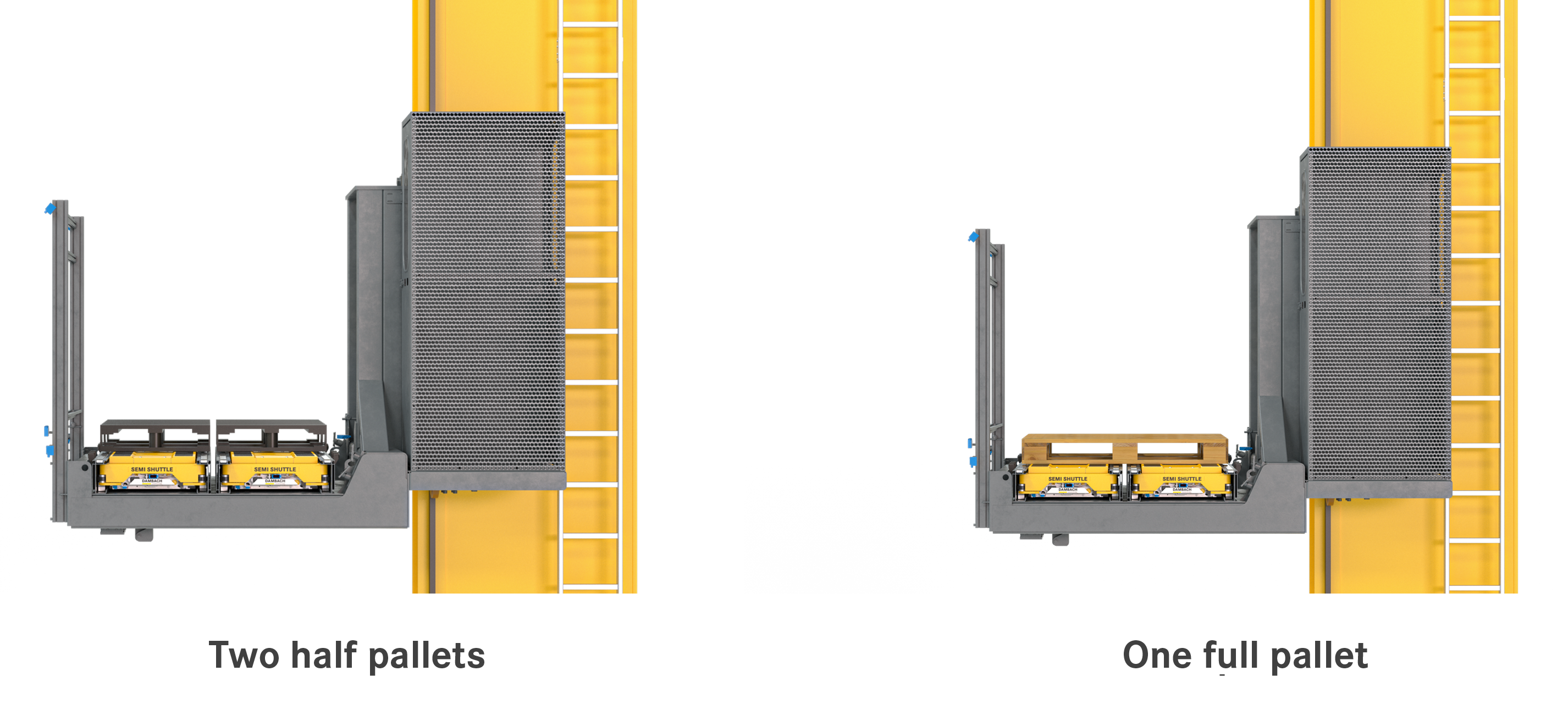

Efficient, flexible and sustainable warehouse management is a decisive factor in intralogistics. In food and beverage retail in particular, the challenge is to store different pallet types in one rack. The DAMBACH SEMI SHUTTLE offers a solution for optimum use of space. The half-pallet shuttle enables the efficient management of Euro pallets and plastic Düsseldorf pallets (KDP) in a single automated storage environment. The special feature is the synchronous operation of two half-pallet shuttles and the independent operation of one shuttle each for transporting a plastic half-pallet.

SEMI Shuttle at a glance:

- Half-pallet shuttle with power caps

- Payload of up to 800 kg per shuttle

- Wireless communication

- On-board control

- Combined function sequence with two half-pallet shuttles possible

- Optimized sensors for black plastic pallets

- All-wheel drive

Fast, Flexible, Reliable

Unique among pallet shuttles

One storage - many possibilities

With a cable-free drive concept, the DAMBACH SEMI SHUTTLE draws its energy from power caps. These are charged during the transfer movement on the storage and retrieval machine in a minimum of 8 seconds, thus enabling 24-hour continuous operation. Thanks to its versatile application options, the SEMI SHUTTLE can flexibly transport both half and full pallets in mixed operation and position them in the right place.

What applications is the SEMI SHUTTLE suitable for?

- Multi-deep storage of pallets with storage and retrieval machines

- Uniform rack structure despite mixed operation

- Independent and synchronous control of the SEMI SHUTTLES

Storage in mixed operation

For optimum storage

The principle

Conventional mixed operation

In conventional mixed operation, a rack structure is used that is specially designed for full pallets. Half pallets are additionally stored on support boards, which leads to increased space requirements and impairs the efficiency of the system. This leads to a loss of space and room due to inefficient use of the available space. The need for support boards increases costs and logistical effort. This conventional method does not offer flexible and optimal use of the warehouse for real mixed operation.

Mixed operation with DAMBACH SEMI SHUTTLE

Storage in mixed operation is based on a pallet-oriented system to store both full and half pallets in one racking system. Various techniques are used to make optimum use of the available space. Full pallets are stored crosswise in the racking, half pallets lengthwise. This combined storage method enables efficient use of the available space and optimizes the storage capacity for a versatile product range in a shelving structure. The racking channels are used via the central web.

Conclusion

- Full and half pallets are stored in a statically favorable position

- Optimum use of space and area

- No need to use support boards

- Different pallet types in one rack

- All channels have the same structure in the rack and can be used flexibly

- Optimum shelf height distribution per level

- Mix of full and half pallets possible in one channel